Kiln Tire Inspection Services

Receive a quote tailored to your needs

Why Choose Kiwa's Kiln Tire Inspection Service?

Kiln tires, which can measure up to 9 meters in diameter and 0.5 meters thick, are prone to cracking due to sand holes, slag, and inclusions in the cast steel. Kiwa’s industrial kiln services and kiln tire maintenance services provide detailed insights into the structural health of your kiln tires, helping to prevent brittle fracture that lead to unplanned outages and expensive repairs.

Key Benefits of Kiln Tire Inspection

Comprehensive Crack Detection: Our phased array ultrasonic testing method identifies both surface and deep subsurface cracks in kiln tires, helping you address issues before they lead to failure.

Reduced Downtime: With regular kiln tire monitoring, you can prevent kiln tire failure. This way you can minimize unexpected shutdowns and keep your operations running smoothly.

Cost-Efficient Maintenance: Proper kiln tire maintenance lowers long-term repair costs by detecting issues early and extending the lifespan of your kiln equipment.

How Kiwa's Kiln Tire Inspection Works

Kiwa uses state-of-the-art phased array ultrasonic testing to assess the entire surface and depth of your kiln tires. This inspection process involves mapping out high-risk areas where cracks and weaknesses may develop, particularly during the critical shutdown cycle when the kiln is cooled and heated again after maintenance. The reheating can lead to brittle fracture, making it essential to monitor these areas closely. Our fracture mechanics analysis predicts when cracks might become critical, allowing for more accurate planning and management of kiln tire maintenance schedules. This way you are on top of your kiln equipment maintenance.

Our experienced experts are available worldwide. We adapt flexibly to your shutdown times. Thanks to automated testing, we keep the measurement time as short as possible. The measurement data is stored digitally so that no information is lost, and any degradation can be detected during recurring tests.

Who Can Benefit from Kiln Tire Inspections?

Our kiln tire inspection services are ideal for asset managers, maintenance teams, and operations managers in industries such as cement, pulp and paper, and any other sector relying on rotary kilns. Protect your investment with our preventive maintenance service and ensure the safety of your equipment. With regular kiln tire crack detection and rotary kiln inspection services from Kiwa you have a good grip on your rotary kiln operations.

FAQs

What is included in the inspection process?

Our inspections involve a complete phased array scan to detect inclusions, damage, and high-risk areas in the kiln tires.

Why should inspections be conducted?

Regular inspections during maintenance cycles are recommended to mitigate risks and maintain operational efficiency.

For more information about our Kiln Tire Inspection Services and how we can help you achieve operational excellence, please contact us.

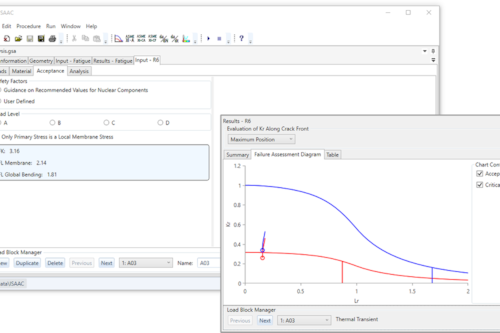

ISAAC - Integrity and Safety Assessment of Components

ISAAC is a software for fracture and Fitness-For-Service (FFS) analyses which includes both crack growth and acceptance assessment procedures for a large number of geometries. Read more about tools and features in ISAAC.

Non-Destructive Testing (NDT)

Check if quality demands are being met with non-destructive testing. Or use NDT testing as part of in-service inspections or preventive maintenance to quantify the status of critical components and equipment.

Asset Integrity Management Consulting

In modern engineering, organizations must consider reliability and integrity across the full lifecycle of critical assets. Reliability thinking must be pushed earlier into the design stage and continuous integrity assessments must be provided to support lifecycle operations.