ATEX Global Software

Receive a quote tailored to your needs

INNOVATION TO ASSURANCE SAFETY IN ATEX / DSEAR or IECEx ATMOSPHERES

Technological innovation in guaranteeing safety in ATEX / DSEAR or IECEx atmospheres is a question that must be addressed not only in the petrochemical industry but in several industries susceptible to explosive atmospheres. There are many industrial activities in which explosive atmospheres (ATEX) exist due to the combustible/flammable nature of the substances that these industries process or store.

- Electricity production

- Chemical industry

- Waste water treatment

- Gas distribution

- Wood processing

- Paint and coating

- Agriculture

- Metallurgy

- Food industry

- Pharmaceutical industry

- Recycling

- Refineries

- Landfills

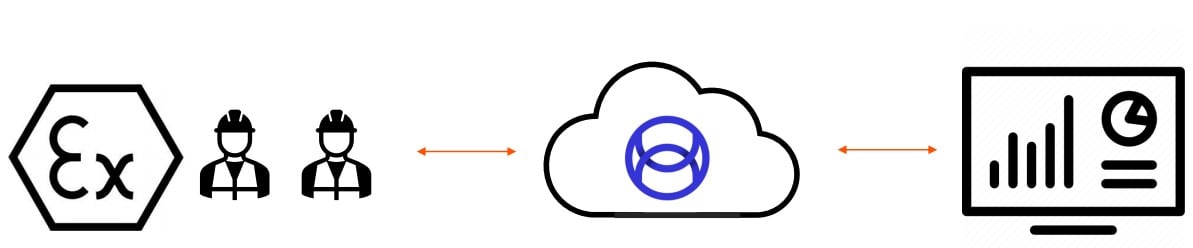

CENTRALIZING INFORMATION SAVES TIME IN RISKY SITUATIONS

The use of technologies offers a more effective predictive and preventive analysis for risk situations in each ATEX area, anticipating possible risks and favoring decision-making in emergency situations.

The response time is immediate as all information is centralized, organized, and accessible to all responsible parties.

Advantages

- Preventing explosions in potentially explosive atmospheres

- Mitigating the risk of accidents

- Ensure regulatory compliance

- Reduced cost of fines

- Reduced insurance premiums

- Enhance your reputation as a safe and reliable company

ATEX, DSEAR, and IECEx are all related to the safety of equipment and systems used in potentially explosive atmospheres. ATEX is a European directive, DSEAR is a set of UK regulations, and IECEx is an international certification system, all working towards the same goal of preventing explosions and ensuring the safety of workers in hazardous environments.

These objectives are achieved through a series of specific requirements, including the classification of areas, risk assessment of personal injury and material damage, the inspection of equipment and systems, the implementation of appropriate safety measures, and the training of employees.

- ATEX Manual revised whenever there are significant changes that affect the safety of operations.

- Frequency of inspections of equipment installed in hazardous areas.

The use of digital tools makes it possible to optimize the flow of information and obtain data in real-time, such as KPIs, high-risk anomalies, and action plans.

- Auditable

- Safe

- Mobility

ATEX Petrochemical

CASE STUDY

The petrochemical company needed to:

- Review the Explosion Protection Manual

- Detailed inspection of electrical, non-electrical, and instrumentation equipment within hazardous areas

- Gap analysis and implementation of minor repairs

- Implementation of a reinspection system

24 Months

+23000 Equipments

9 Sites

+960000 M2

The project involved:

- 2 ATEX experts

- 14 inspetors and backoffice technicians

Were developed:

- more than 23.000 inspections and equipments

- more than 68.000 fitness for purpose (gap analysis)

- more than 49.000 action plans

- more than 2.000 earth continuity measurements

- placed more than 500 identification smart tags

- placed more than 1,600 cable tags

Job description

CREATION/REVISION OF THE ATEX MANUAL

Tasks performed:

- Explosivity analysis of various dust samples

- Operational data analysis

- Simulations using Phast software

- Risk assessment of damage and material

- Documental Revision

- Revision of area classification drawings

FIELD INSPECTION

Inspections were carried out in accordance with the IEC 60079 standard on the:

- electrical equipment

- Non-Electrical equipment

- Instrumentation equipment

The ATEX module was used to carry out the inspections, collecting all the evidence (photographs, videos, text).

All actions and indicators are generated in real time.

GAP IDENTIFICATION AND ACTIONS RECOMMENDATIONS

By geo-referencing the equipment and comparing it with the plans produced, we check that the equipment is in accordance with the needs of the site.

During the inspection we check all the applicable points of the IEC standard checklists, ensuring that anomalies are identified and can be repaired.

ACTION PLAN + REINSPECTION

For each one of the identified GAP, were defined mitigation actions.

After the action was implemented, re-inspections were carried out.

PERIODIC INSPECTIONS

Periodic inspections are essential to ensure that installations are kept in satisfactory condition.

The ATEX module allows us to define inspection periods, ensuring that we have vision and control over inspections.

TRAINING

Training activities were carried out (legal obligation)

- 3 training sessions were held

- 2 online training actions were made available