Damage analysis heat distribution networks

Receive a quote tailored to your needs

Our expertise

- Independent damage analysis: We gather information (through literature review), develop a step-by-step plan and conduct a thorough analysis to determine the cause of the damage.

- Residual quality assessment: Besides identifying the cause of damage, we examine similar network segments to assess whether they are near end-of-life and may also require replacement. Our lab is equipped for chemical and physical analyses, mechanical testing and microscopy.

Why choose Kiwa?

- Experience and expertise: Decades of experience in damage investigations and technical analyses. Network operators, insurers, and government bodies, including justice and law enforcement agencies, have relied on us for years.

- Modern laboratory: Equipped for comprehensive testing and trials.

- Targeted advice: We offer guidance to help prevent future failures and to support well-informed decisions on network maintenance and replacement.

Choose Kiwa Technology for reliable damage analysis and quality assessment of your heat distribution network. Visit our laboratory and see how we can help keep your network in top condition.

Go backstage

Take a step inside our technology lab!

Test possibilities materials

At Kiwa Technology, we have years of experience conducting independent damage and material investigations for a wide range of market players, including energy companies, water utilities, contractors, suppliers, manufacturers and insurance companies. Our expertise focuses on pipes and components for energy and water, made from various materials such as copper, steel, plastics and glass fiber-reinforced composites.

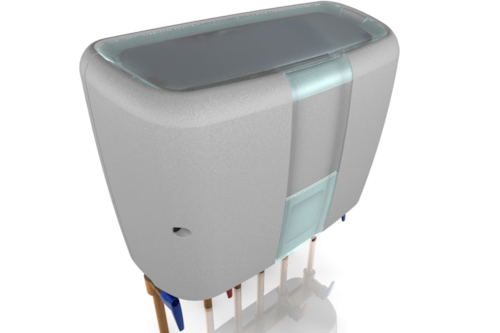

Product assessments heat distribution

Do you have a new product in heat distribution, such as a delivery set or heat pump system, or are you in the process of developing one? Ensure your product meets all standards and performs optimally with Kiwa Technology's expertise.

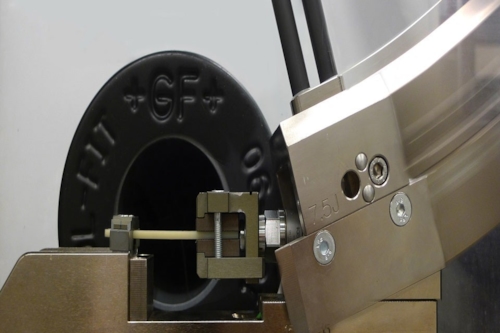

Jointing techniques materials

Problems in pipeline systems often arise at the connections. At Kiwa Technology, we have years of experience investigating and identifying the causes of connection failures. Our expertise in welding plastic pipes (PE, PEX, PA, PP, etc.) and other joining techniques forms the foundation of our high-quality consultancy and research and development projects.

Sleeve connection assessment for heat distribution networks

The reliability of district heating networks heavily depends on the quality of pipeline connections. Water ingress at socket connections can compromise insulation, leading to reduced thermal efficiency and corrosion in steel pipes. It is crucial for both operators and contractors to ensure that socket connections are correctly installed to avoid costly future leaks.

Tensile impact test plastic according to ASTM D1822 or ISO 8256

Plastic pipes and components are often used for water and other underground infrastructures. Detailed knowledge of the properties of plastics is indispensable to ensure that these materials can perform well for years to come.

Reliable delivery sets for heating, cooling and hot water

A reliable delivery set is essential for the efficient and comfortable supply of heating, cooling and/or hot water. But how can you be sure that your delivery sets function properly and meet all requirements? At Kiwa, we combine technical expertise with practical solutions. We assist you with the selection, installation and management of delivery sets and act as an independent partner in case of disputes. Together, we ensure that your system is reliable and future-proof.