Destructive and non-destructive testing electrofusion joints

Receive a quote tailored to your needs

Electrofusion is a well-known technique. In 2016, all knowledge was bundled in the Dutch quality standard ‘NTA 8828 Electrofusion of PE pipes and PE fittings’. The last revision dates from 2019. Based on the NTA 8828, there is also a certification system for electrofusion professionals and supervisors.

Destructive welding test

In addition to this, network operators sometimes prescribe that several joints made on-site in a project are removed for laboratory research. For example, the quality of the welds could be demonstrated visually or destructively. If this shows leakages or other problems, the network operators could have more investigations carried out and, based on this, estimate the cause and extent of the problem.

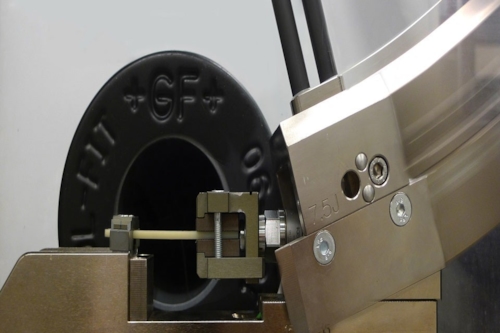

Non-destructive welding examination with PAUT

A relatively new way to determine the quality of electrofusion joints, without actually having to remove the weld and bring it to a laboratory, is non-destructive testing using Phased Array Ultrasonic Testing (PAUT). Kiwa uses PAUT in the field to examine the entire welding surface and to assess deviations and defects such as embedded contaminants, air cavities, and an incomplete insertion depth.

Tensile impact test plastic according to ASTM D1822 or ISO 8256

Plastic pipes and components are often used for water and other underground infrastructures. Detailed knowledge of the properties of plastics is indispensable to ensure that these materials can perform well for years to come.

Jointing techniques materials

Problems in pipeline systems often arise at the connections. At Kiwa Technology, we have years of experience investigating and identifying the causes of connection failures. Our expertise in welding plastic pipes (PE, PEX, PA, PP, etc.) and other joining techniques forms the foundation of our high-quality consultancy and research and development projects.

Permeation and chemical compatibility

Kiwa is your partner for assessing the chemical compatibility and material performance of applied materials and the corresponding tests like permeation, immersion or rapid gas decompression tests. Testing material samples, pipes, components or even complete systems is possible.

Go backstage

Take a step inside our technology lab!